- cold rolled ribbed steel bar machine process

Summary

■ Composition:Cold rolled ribbed bar and wire machine mainly composed of dephosphorization machine,driving and drived rolling mill,Medium frequency heat treatment device,CNC fly shear,speed detector,automatical upender or coiled reinforced bar device,baler etc.

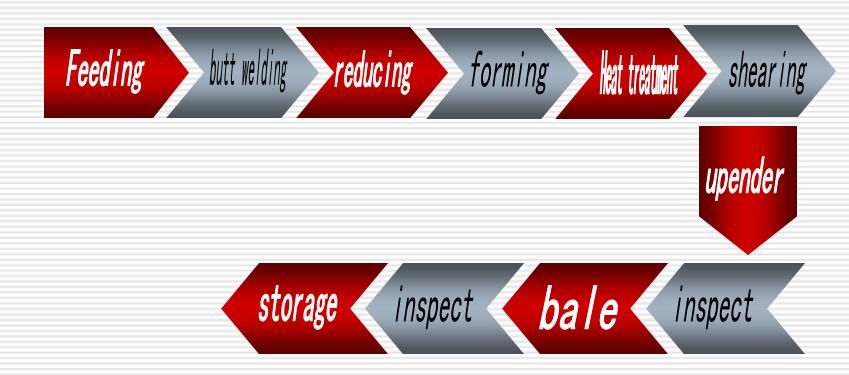

■ Principle:ordinary carbon steel as material, through reducing the diameter,forming and heat treatment to improve the material grain boundary organization distribution, Improve the physical properties, automatically sizing ,cutting and baling to storage.

■ Features:

1. Adopting driving and drived rolling mill structural style,one time reducing and one time formaing technical production process; adjustable-velocity,Easily change roller,easy operation;Solving the old process,poor product quality and hard operation etc problems of traditional cold rolling rebar machine.

2. This production line adopts on line heat treatment, on line control, on line quality inspection etc technology,Automatically,high speed continuously operating, the mechanical property of the cold rolled ribbed bar and wire is over national standard GB13788, and achieving hot rolling III Grade steel standard.

3. Full automatic 10M

4. Full automatic 12M

5. Coiled cold rolled ribbed bar production line

Cold rolled ribbed bar machine parameter

■ Length≈40m Width≈5.5m

■ Max speed:V=180m/min

■ Rebar range:Ф5.5-Ф12mm

■ Max vibration severity:Vm≤2.8 mm/s

■ Max noise:≤85dB

■ Max temperature rise of bearing:t<60℃

■ Model for option:1,Standard 10M 2,Standard12M

If you want know more about Cold rolled ribbed bar and wire machine,please contact us.

Phone(Whatsapp): 008618530605031

Email: info@coldrollingmachine.com

Web: http://www.coldrollingmachine.com

China Economic daily in 29th December,2015 reported Heli Company

/in News /by Cold rolling millChina Economic daily in 29th December,2015 reported Heli Company.

Anyang Heli Company developed new technology in ribbed steel bar with improved elongation.The high elongtion cold rolled ribbed bar line realize large-scale equipments,continuous, automated. This technology is the new mainstay of construction.

Process of cold rolled ribbed bar and wire machine

/in cold rolled ribbed bar machine technology /by Cold rolling millSummary

■ Composition:Cold rolled ribbed bar and wire machine mainly composed of dephosphorization machine,driving and drived rolling mill,Medium frequency heat treatment device,CNC fly shear,speed detector,automatical upender or coiled reinforced bar device,baler etc.

■ Principle:ordinary carbon steel as material, through reducing the diameter,forming and heat treatment to improve the material grain boundary organization distribution, Improve the physical properties, automatically sizing ,cutting and baling to storage.

■ Features:

1. Adopting driving and drived rolling mill structural style,one time reducing and one time formaing technical production process; adjustable-velocity,Easily change roller,easy operation;Solving the old process,poor product quality and hard operation etc problems of traditional cold rolling rebar machine.

2. This production line adopts on line heat treatment, on line control, on line quality inspection etc technology,Automatically,high speed continuously operating, the mechanical property of the cold rolled ribbed bar and wire is over national standard GB13788, and achieving hot rolling III Grade steel standard.

3. Full automatic 10M

4. Full automatic 12M

5. Coiled cold rolled ribbed bar production line

Cold rolled ribbed bar machine parameter

■ Length≈40m Width≈5.5m

■ Max speed:V=180m/min

■ Rebar range:Ф5.5-Ф12mm

■ Max vibration severity:Vm≤2.8 mm/s

■ Max noise:≤85dB

■ Max temperature rise of bearing:t<60℃

■ Model for option:1,Standard 10M 2,Standard12M

If you want know more about Cold rolled ribbed bar and wire machine,please contact us.

Phone(Whatsapp): 008618530605031

Email: info@coldrollingmachine.com

Web: http://www.coldrollingmachine.com

Character of cold rolled ribbed reinforced bar

/in cold rolled ribbed bar machine technology /by Cold rolling millReinforced bar is the “rib” of buildings, While natural disaster(e.g. earthquake, waterflood,

strong wind, natural disaster etc); the unnatural disasters(e.g. the surface collapse caused

by subsurface excavation and excessive extraction of groundwater) happened, Good quality can

ensure the building resist instantaneous collapse and broken, Thus to win valuable time, ensure

to escape successfully from disaster.

This is the basic trait of high ductility cold rolled ribbed reinforced bar product.

Sri Lanka customer visited our company for the cold rolled ribbed bar production line

/in international communication /by Cold rolling millSri Lanka customer visited our company for the cold rolled ribbed bar production line

Uzbekistan customer visited our company for the cold rolled ribbed bar production line

/in international communication /by Cold rolling millUzbekistan customer visited our company for the cold rolled ribbed bar production line

Philippine customer visited our company for the cold rolled ribbed bar production line

/in international communication /by Cold rolling millHebei Haitian Construction Group bought 50 cold rolling lines

/in News /by Cold rolling millHebei Haitian Construction Group bought 50 steel bar cold rolling lines.The production rate will reach to 8 million Ton per year.

Thailand customer visited our company for the cold rolled ribbed bar production line

/in international communication /by Cold rolling millThailand customer visited our company for the cold rolled ribbed bar production line

Heli techtronic

/in News /by Cold rolling millhttp://www.coldrollingmachine.com

Do the best!