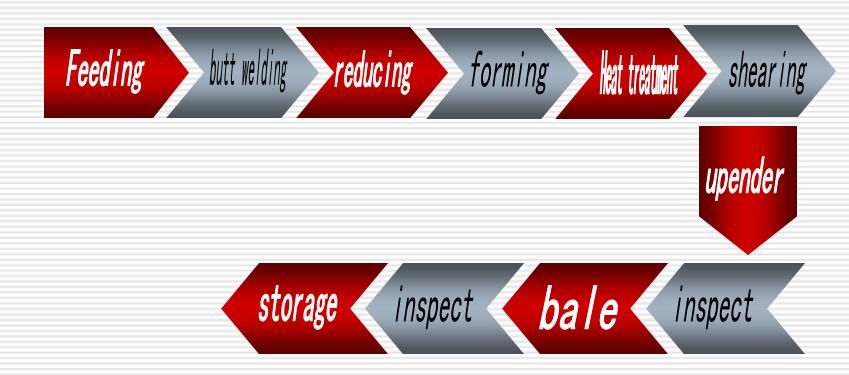

Process of cold rolled ribbed bar and wire machine

Summary

■ Composition:Cold rolled ribbed bar and wire machine mainly composed of dephosphorization machine,driving and drived rolling mill,Medium frequency heat treatment device,CNC fly shear,speed detector,automatical upender or coiled reinforced bar device,baler etc.

■ Principle:ordinary carbon steel as material, through reducing the diameter,forming and heat treatment to improve the material grain boundary organization distribution, Improve the physical properties, automatically sizing ,cutting and baling to storage.

■ Features:

1. Adopting driving and drived rolling mill structural style,one time reducing and one time formaing technical production process; adjustable-velocity,Easily change roller,easy operation;Solving the old process,poor product quality and hard operation etc problems of traditional cold rolling rebar machine.

2. This production line adopts on line heat treatment, on line control, on line quality inspection etc technology,Automatically,high speed continuously operating, the mechanical property of the cold rolled ribbed bar and wire is over national standard GB13788, and achieving hot rolling III Grade steel standard.

3. Full automatic 10M

4. Full automatic 12M

5. Coiled cold rolled ribbed bar production line

Cold rolled ribbed bar machine parameter

■ Length≈40m Width≈5.5m

■ Max speed:V=180m/min

■ Rebar range:Ф5.5-Ф12mm

■ Max vibration severity:Vm≤2.8 mm/s

■ Max noise:≤85dB

■ Max temperature rise of bearing:t<60℃

■ Model for option:1,Standard 10M 2,Standard12M

If you want know more about Cold rolled ribbed bar and wire machine,please contact us.

Phone(Whatsapp): 008618530605031

Email: info@coldrollingmachine.com

Web: http://www.coldrollingmachine.com